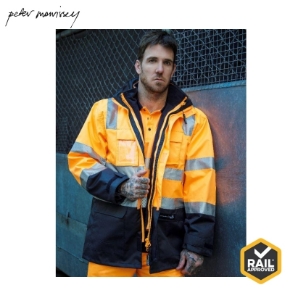

With the introduction of the AS/NZS 1906.4:2023 standard, industrial workwear has seen an exciting expansion in colour options, including vibrant pinks and greens. This enhancement not only improves the visual appeal of safety garments but also emphasises the need for robust dyeing processes that ensure these colours withstand harsh industrial conditions. In this blog, we delve into vat dyeing and reactive dyeing, comparing their effectiveness in terms of longevity against industrial washing and UV exposure.

Vat Dyeing: Pros and Cons

Pros:

- Superior Durability: Vat dyes are renowned for their incredible colourfastness, primarily because the dye molecules convert into insoluble compounds that penetrate deep into the fibre. This deep penetration ensures that the colour remains vibrant even after prolonged exposure to industrial conditions.

- Resistance to Fading: Ideal for outdoor workwear, vat dyeing offers excellent resistance to UV rays, helping maintain the fabric’s original colour despite constant sun exposure.

Cons:

- Limited Colour Vibrancy: While vat dyes are durable, they tend to offer a more muted colour palette, which can be a drawback for industries looking to implement the brighter hues allowed under the new standard. Passing Class F or NF under AS/NZS 1906.4:2023 becomes more difficult through this process but if the right vibrancy can be achieved, a long-lasting colourfast fabric is the result.

- Complex Process: The vat dyeing process is more labour-intensive and chemically complex, potentially leading to higher production costs.

Reactive Dyeing: Pros and Cons

Pros:

- Vibrant Colours: Reactive dyes are celebrated for their bright and vivid colour output specified in AS/NZS 1906.4:2023.

- Excellent Wash Fastness: These dyes form covalent bonds with the fibre, making the colour highly resistant to washing. This property is crucial for workwear subjected to frequent and rigorous cleaning cycles.

Cons:

- UV Sensitivity: Despite their resilience to washing, reactive dyes are somewhat more susceptible to fading when exposed to prolonged sunlight, which can be problematic for outdoor applications.

- Chemical Sensitivity: The reactive dyeing process can be sensitive to the conditions under which it is performed, requiring precise control of temperature and pH to ensure optimal results.

Ensuring Durability in Industrial Workwear

The choice between vat and reactive dyeing for industrial workwear hinges on the specific requirements of the job environment. Vat dyeing is preferable for garments exposed to extensive outdoor conditions due to its superior UV resistance, while reactive dyeing is ideal for environments where garments undergo frequent industrial washes thanks to its exceptional wash fastness.

For manufacturers, the decision involves balancing these benefits against the intended use of the workwear, ensuring that the garments not only meet safety standards but also retain their functional and aesthetic qualities throughout their lifecycle.

As the industrial workwear sector adapts to the new AS/NZS 1906.4:2023 colour standards, understanding the distinct advantages and limitations of vat and reactive dyeing techniques is essential. Both methods offer unique benefits for maintaining the colourfastness and durability of workwear, making them invaluable in meeting both safety and performance criteria.

Contact us today to discover the Tru Workwear range most suits to your businesses needs.