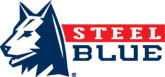

In Australia's demanding work environments, particularly within construction, mining, and industrial sectors, the significance of breathable workwear cannot be overstated. The nation's climate, characterised by high temperatures and humidity, necessitates garments that not only ensure safety but also provide comfort.

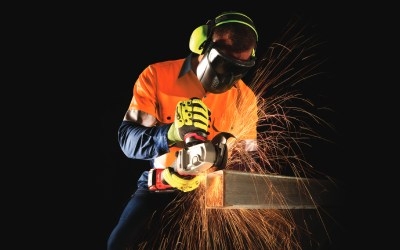

The process of applying tape patterns to workwear is crucial in ensuring that the tape is securely attached and remains visible during use. Tape patterns are applied to safety garments through various methods such as heat press, sewing and adhesive bonding.

In the realm of industrial safety, high-visibility (hi-vis) garments are indispensable. However, maintaining their colour integrity and visibility is a challenge due to varying environmental conditions and the rigorous demands of industrial use. In this exploration, we'll delve into how different fibres like cotton and polyester withstand colour fading, the impacts of UV exposure, and the rigours of industrial washing.

Safety is a top priority in any workplace, and protective workwear is crucial in keeping workers safe from on-the-job hazards. While all workwear must meet safety standards and regulations, there are significant differences between certified and compliant workwear. It is essential to understand why certified workwear is safer than compliant workwear. By understanding the benefits of certified workwear, you can make informed decisions about choosing the correct workwear to keep yourself and your colleagues safe in the industry.

Reflective Tape Types Saturday, 26 April 2025 Reflective tapes play a crucial role in workwear of various industries, with standard tape, perforated tape, and segmented tape being the most widely used types. Reflective tape enhances visibility in low light conditions, perforated tape facilitates air circulation to keep workers cool in hot environments, and segmented tapes are lightweight as they are heat sealed on and provide enhanced movement and flexibility. These types of tapes enhance safety and productivity in different industries by addressing specific needs and requirements.

When it comes to sourcing workwear uniforms and safety PPE for your business, making the right choice isn’t just about compliance, it’s about protecting your team, ensuring professional presentation, and building trust with your clients. Workwear Direct has established itself as Australia’s leading provider in this space, thanks to our extensive experience, product range, and customer-focused services.

Tape patterns are vital in enhancing safety and visibility in various industries. Tape patterns have become essential in workwear, from construction sites and roadways to industrial settings. Explore how tape patterns contribute to a safer and more secure work environment.

_400.jpeg)