Australia’s diverse and challenging work environments demand more from Personal Protective Equipment (PPE). Whether it's enduring the blazing sun, staying hydrated in arid condition, or ensuring breathability for long hours of work, the right PPE is crucial for worker safety and productivity. Workwear Direct and TRu Brands, are dedicated to providing innovative PPE solutions tailored for these unique conditions. From breathable fabrics to advanced UV protection, our products deliver both safety and performance. Here’s how our market-leading solutions can transform your worksite.

In Australia’s construction and mining industries, Personal Protective Equipment (PPE) is indispensable for safety, but its disposal poses a significant environmental challenge. Safe Work Australia reports that these sectors generate substantial waste, with PPE contributing to landfill pollution and resource loss. End-of-life (EOL) solutions are critical to close the loop, and The PPE Group’s 360processed program - partnering with Upparel - provides a comprehensive recycling pathway. This initiative diverts PPE from landfills, upcycles materials, and offers transparent reporting, ensuring a sustainable afterlife for gear. Discover how 360processed addresses EOL issues and why it’s essential for sustainability managers.

For Work Health and Safety (WHS) Managers in Australia’s construction and mining industries, ensuring worker compliance with Personal Protective Equipment (PPE) is a daily challenge. Safe Work Australia reports that non-compliance contributes to 40% of workplace injuries, costing businesses millions in medical expenses and downtime. A critical pain point is lack of worker awareness about the importance of PPE, often due to inadequate training or skepticism about its effectiveness. The PPE Group’s brands—Force360, TRu Workwear, Graphex, and Bool PT—combine high-performance safety with comfort to make PPE indispensable, while our engaging toolbox talks reinforce awareness. Here’s how we help WHS Managers boost compliance and keep workers safe.

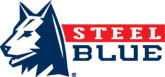

In Australia’s high-risk mining and construction industries, personal protective equipment (PPE) is more than just gear - it’s a lifeline. Despite stringent safety regulations, non-compliance with PPE usage remains a persistent issue, leading to lost time injuries (LTIs), operational disruptions, and significant financial burdens. At Private Brands, we understand the critical role our certified PPE and workwear ranges, including Force360, Graphex, Bool PT FR workwear, and TRu Workwear high-visibility workwear, plays in preventing these costly consequences. Let’s explore the true cost of not wearing PPE, the impact on subcontractors, and why investing in quality PPE is a game-changer for both business and worker safety.

In Australia’s construction and mining industries, ensuring workers wear Personal Protective Equipment (PPE) consistently is a constant challenge for Work Health and Safety (WHS) Managers. Non-compliance can lead to serious injuries, with Safe Work Australia reporting that up to 40% of workplace injuries are linked to improper or absent PPE use. One of the most significant pain points driving this issue is worker discomfort, which causes resistance to wearing PPE for long shifts in demanding environments. The PPE Group’s innovative brands—Force360, TRu Workwear, Graphex, and Bool PT—are designed to tackle this problem head-on by prioritising comfort without compromising safety.

It is a fact that too much noise onsite can lead to temporary or permanent hearing loss or tinnitus – defined by ringing in the ears. The most at risk category of workers is industrial manufacturing workers who rely on their PPE to protect them from Noise-Induced Hearing Loss (NIHL). NIHL can be brought upon by long-term exposure to harmful levels of sounds. With Force360 certified hearing protection you are guaranteed protection for the stipulated dB classification, as tested to Australian standards. However, as we know there are more factors at play when preventing a team from hearing injuries. How effective is hearing protection is being used?

It's important to understand that waterproof gloves and water-resistant gloves are designed for different purposes. Water-resistant gloves provide some protection against water, but they are not entirely waterproof. Waterproof gloves are impermeable to water keeping your hands completely dry even when fully submerged. Explore the differences and advantages of water-resistant gloves.

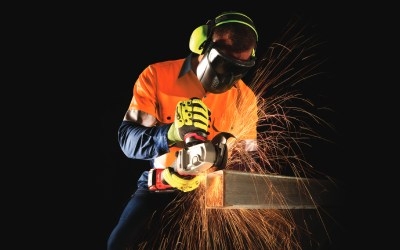

Safety is a top priority in any workplace, and protective workwear is crucial in keeping workers safe from on-the-job hazards. While all workwear must meet safety standards and regulations, there are significant differences between certified and compliant workwear. It is essential to understand why certified workwear is safer than compliant workwear. By understanding the benefits of certified workwear, you can make informed decisions about choosing the correct workwear to keep yourself and your colleagues safe in the industry.

When it comes to sourcing workwear uniforms and safety PPE for your business, making the right choice isn’t just about compliance, it’s about protecting your team, ensuring professional presentation, and building trust with your clients. Workwear Direct has established itself as Australia’s leading provider in this space, thanks to our extensive experience, product range, and customer-focused services.

Working with hazardous chemicals? Learn how to prevent accidents and create a safe work environment. Risk assessment, safe work practices, and proper PPE are all essential.

Elevate your team's performance with top-notch workwear from Workwear Direct. Safety, style, and customization – your one-stop solution. #WearForLife

ACT: repeat offenders in residential construction on notice There has been little change in safety behaviours and recurrent non-compliance by a number of residential construction businesses in the ACT, despite repeated enforcement notices and engagement with WorkSafe ACT inspectors, according to the regulator.